The energy landscape is shifting rapidly. Driven by the explosive growth of AI data centers and electrification of transport, heating, industry and more, electricity demand is climbing sharply after two decades of virtually stagnant growth.

In this environment, securing sufficient power for large-scale operators has become a massive operational bottleneck. Utility interconnection queues in major data centers average over four years—double what they were in the previous decade.

To circumvent these delays, industrial facilities are increasingly exploring building on-site battery energy storage systems (BESS) or developing entire self-sufficient microgrids that consist of a diverse configuration of energy solutions.

Beyond simply acting as a workaround for lengthy utility queues, BESS provides heavy industry with a powerful toolkit for financial and operational efficiency. Batteries can supply energy-intensive facilities during peak demand periods so they avoid using the grid during its most expensive hours. Batteries are also one of the few solutions that can provide dynamic load response where batteries act as an immediate, dynamic buffer against sudden fluctuations in power demand.

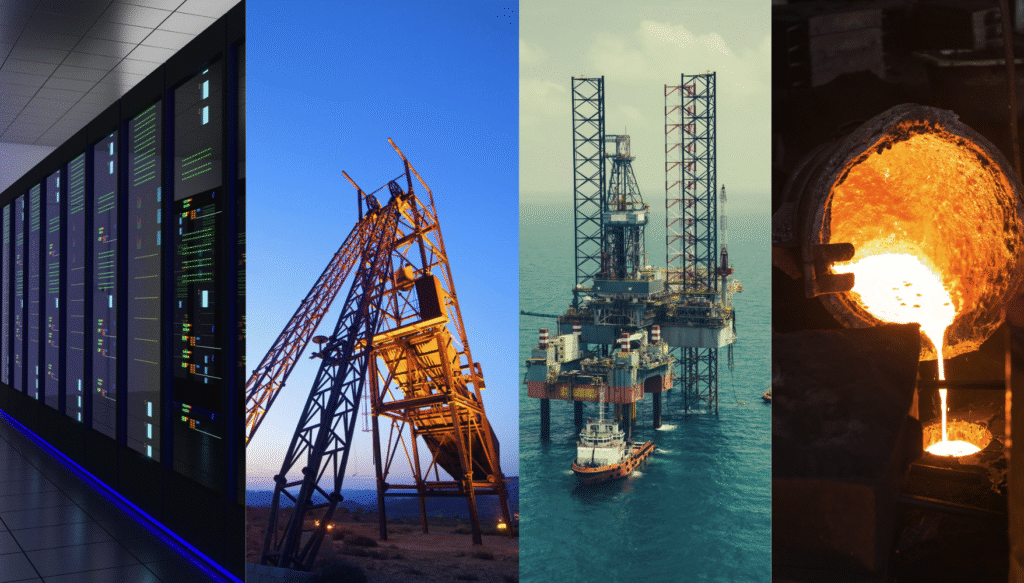

To set the stage for what may become more common, this blog post demonstrates how batteries have been utilized to manage massive industrial loads, with five real-world examples from five heavy industries.

1. BESS for Powering Data Centers

While data centers have not traditionally been classified as heavy industry, the rapid emergence of hyperscale data centers—with power demands rivaling industrial facilities—is beginning to blur that distinction.

To serve hyperscalers like Meta, Amazon, and Google, server racks have grown eight to ten times more power dense than traditional models and depend on having power available 24 hours a day, every day of the year, to avoid serious disruptions to global data infrastructure. Data centers are reliant on diesel backup generators and other redundancies to prevent any interruptions to their operations, but that is set to change with pledges from tech giants to power their data centers with clean energy.

For example, Google recently partnered with Energy Dome to deploy commercial-scale long-duration CO2 batteries. These systems provide scalable, carbon-free backup power, effectively replacing traditional diesel setups. Furthermore, utilities recognize the strain hyperscale facilities place on local infrastructure. Energy providers like Alliant Energy are building massive utility-scale BESS facilities—such as their 75 MW and 100 MW projects—specifically to stabilize the grid and ensure new data center developments receive reliable power.

2. Using BESS in Steel and Metal Manufacturing

Steel manufacturing alone accounts for roughly 7% of human greenhouse gas emissions. That’s more emissions than either the European Union or Russia produce on an annual basis. In metals manufacturing, as in many other industrial sectors, the major appeal of BESS is its potential for lowering operational costs through peak shaving and load shifting to avoid peak demand charges from the utility.

That is exactly what Schnitzer Steel Industries, Inc. sought to accomplish when they partnered with Powerflex in 2021 to install and operate a 1.6 MW / 5.5 MWh BESS in Oakland, California. Schnitzer’s Oakland facility processes and recycles ferrous and nonferrous metals, creating both “substantial and variable” demand for electricity. The BESS is configured to charge and discharge in a fashion that reduces the peak levels of consumption, thereby reducing overall peak power demand and cost.

3. Oil & Gas Rigs

The oil and gas industry has taken a liking to battery energy storage systems for a couple of good reasons. When used in a hybrid format, batteries allow operators to reduce the run time of diesel engines and also keep them operating at a level where efficiency is maximized. This extends the life of generators, which usually aren’t designed to handle smaller loads.

Further, battery-drawn energy is available immediately and this improves the dynamic operation of engines, which makes a big difference on off-shore rigs that have highly variable power demand. Incorporating batteries on rigs also offers a much smaller power plant footprint compared to traditional power schemes using gas turbines. Swedish lithium-ion battery provider Echandia deployed a hybrid system on a jackup drilling rig in the Middle East in 2023. According to the company, the hybridization of the rig will help eliminate peak loads that would otherwise require multiple generators to operate under off-design conditions.

4. Manufacturing of Cement & Concrete

Cement & concrete is a tricky one because most of the emissions come from process rather than energy consumption – i.e. the feedstock materials that release embodied carbon during processing. While other low-carbon alternatives are poised to make the biggest dent in this industry, the potential of BESS in reducing operating costs and managing energy consumption is still very promising.

Building materials group Holcim partnered with TotalEnergies in 2023 to deploy a solar PV and battery storage system at Holcim’s cement plan in Colorado. It is expected to cover around 40% of energy demand at the plant which produces 1.8 million tonnes of various grades of cement per year. Through the power purchase agreement (PPA) between the two, Holcim will receive roughly 71,000 MWh of power per year. A major function of the battery storage system is reducing the cement plant’s draw of power from the grid during peak demand periods.

5. BESS Usage in Mining & Other Forms of Extraction

Because mining operations, like gas and oil extraction facilities, are often located in remote regions, BESS offers an attractive solution to provide these places clean, reliable power at stable prices. Mining is an incredibly energy-intensive process, with energy expenses often accounting for 40% of a mine’s total operating costs. Transporting diesel fuel to these far-flung locations simply adds immense logistical overhead.

In Australia, mining giant BHP and energy provider TransAlta partnered to build a new solar farm in the Northern Goldfields. The project, comprised of two solar farms with 38.1 MW capacity and a 10.1 MW/5.4 MWh battery energy storage system, is stated to help BHP reduce scope 2 emissions at its Nickel West northern operations by 12 percent. The facility is one of the world’s largest off-grid mining solar and battery energy storage systems and features about 70,000 solar panels across 90 hectares of land. The initiative will replace power currently generated from diesel and gas.

With New Solutions, The Future of BESS in Industry is Looking Bright

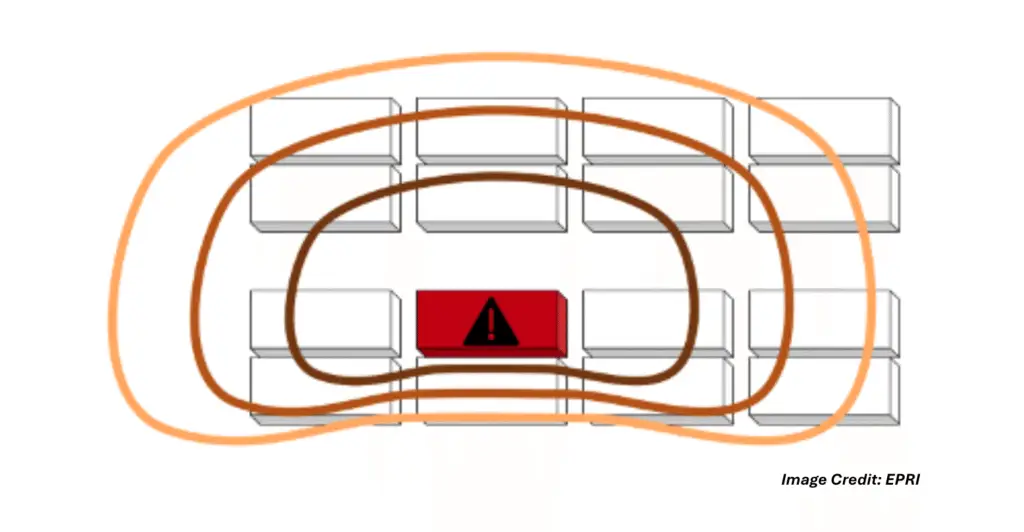

The outlook for speed and efficiency in industrial applications by leveraging the power of BESS is encouraging, to say the least. The potential for BESS in energy-intensive use cases like industry is huge, but to unlock this opportunity particularly for the onslaught of new data centers, new types of non-lithium batteries are needed. Especially where there are elevated hazards, on oil & gas rigs or steel plants, for example, or exposure to the elements, the flammable nature of lithium-based batteries isn’t scalable. A battery that can withstand a wide operating temperature range, perform versatile functions, and that cannot go into thermal runaway changes the equation entirely, spurring adoption in industries that need to manage their energy consumption.

To turn the tide in a meaningful way and transcend the limitations of lithium-ion, Alsym is bringing to market a new era of high-performance, non-flammable battery storage solutions. To learn more about what Alsym is doing to enable BESS adoption in demanding industrial applications, contact us today.